For a decade, High QA software has digitized, simplified and automated the way companies plan their manufacturing quality. Discover how over 1,300 companies are using it to win in their markets.

HQA 360: Learn to Plan Better

Improving Manufacturing Quality Planning with High QA

Join us for a free 30-minute webinar and discover the secret to 5x faster quality plans. High QA’s innovative solutions digitize, streamline and automate your manufacturing quality planning processes.

An hour of planning can save you hours of doing.

Learn how to:

- Automate routine tasks: Eliminate time-consuming manual processes for ballooning, GD&T extraction and quality planning.

- Capture design data: Seamlessly integrate design information into your quality management system for efficient workflow.

- Unify your quality processes: Manage all your quality data in a single, centralized database for improved visibility and control.

This webinar is ideal for:

- Manufacturing professionals seeking to improve efficiency and reduce costs.

- Quality managers looking to automate manual tasks and streamline workflows.

- Anyone interested in leveraging technology to enhance manufacturing quality processes.

Register now to:

- Gain valuable insights into the latest manufacturing quality trends.

- Explore real-world examples of how High QA is helping manufacturing businesses succeed.

- Ask questions and get expert advice from our manufacturing quality management specialists.

Select the Best Time For You

This webinar will be held at two different times. If neither of those times is convenient for you, registered attendees will receive an email with a link to the recorded webinar.

Wednesday, February 28, 2024

11:00 AM Eastern Time

(US and Canada)

Los Angeles: 8:00 AM

New York: 11:00 AM

London: 4:00 PM

Bengaluru: 9:30 PM

Tokyo: 1:00 AM

Wednesday, February 28, 2024

6:00 PM Eastern Time

(US and Canada)

Los Angeles: 3:00 PM

New York: 6:00 PM

London: 11:00 PM

Bengaluru: 4:30 AM (next day)

Tokyo: 8:00 AM (next day)

Tour the Future of

Manufacturing Quality Management

and Supplier Quality Management

Introducing High QA, HQA 360 and HQA HUB

Who is High QA?

For almost a decade, High QA has simplified the way we manage manufacturing quality with advanced software. Discover how over 1,200 companies are using it to win in their markets.

Invest less than an hour to learn about High QA and its solutions that automate routine and time-consuming processes to collect and process manufacturing quality data in a single database from quotation to acceptance of reports.

Learn how to:

- Plan a part for quality in minute vs. hours.

- Collect data from CMM instantly.

- Produce quality reports in just a few hours vs. days.

- Use quality data to collaborate with your suppliers and customers to remove costly inspections.

What is a Quality Management Suite (QMS)?

A quality management suite (QMS) is aimed at manufacturing quality management inside a facility, division, or enterprise.

HQA 360 helps:

- Create planning documents at the quotation stage to evaluate risks.

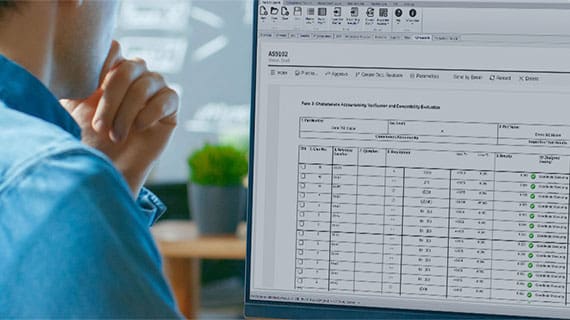

- Accelerate planning processes with tools such as ballooning 2D drawings or 3D models to help operations focus on what to measure and how.

- Capture data from manual inspection devices and connected machines.

- Analyze complex data and generate reports for FAI or APQP/PPAP.

What is Supplier Quality Management (SQM)?

A supplier exchange portal where the quality is at the center of the collaboration.

HQA HUB helps:

- Unify quality data in one centralized place regardless of supplier location.

- Collect and exchange manufacturing quality data on a secure system.

- Mitigate potentially costly supplier certifications and inspections.

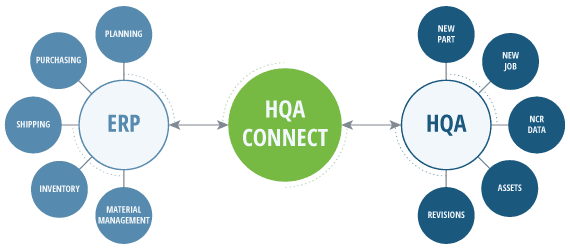

Why Should You Connect Your ERP with Your Manufacturing Quality System?

High QA

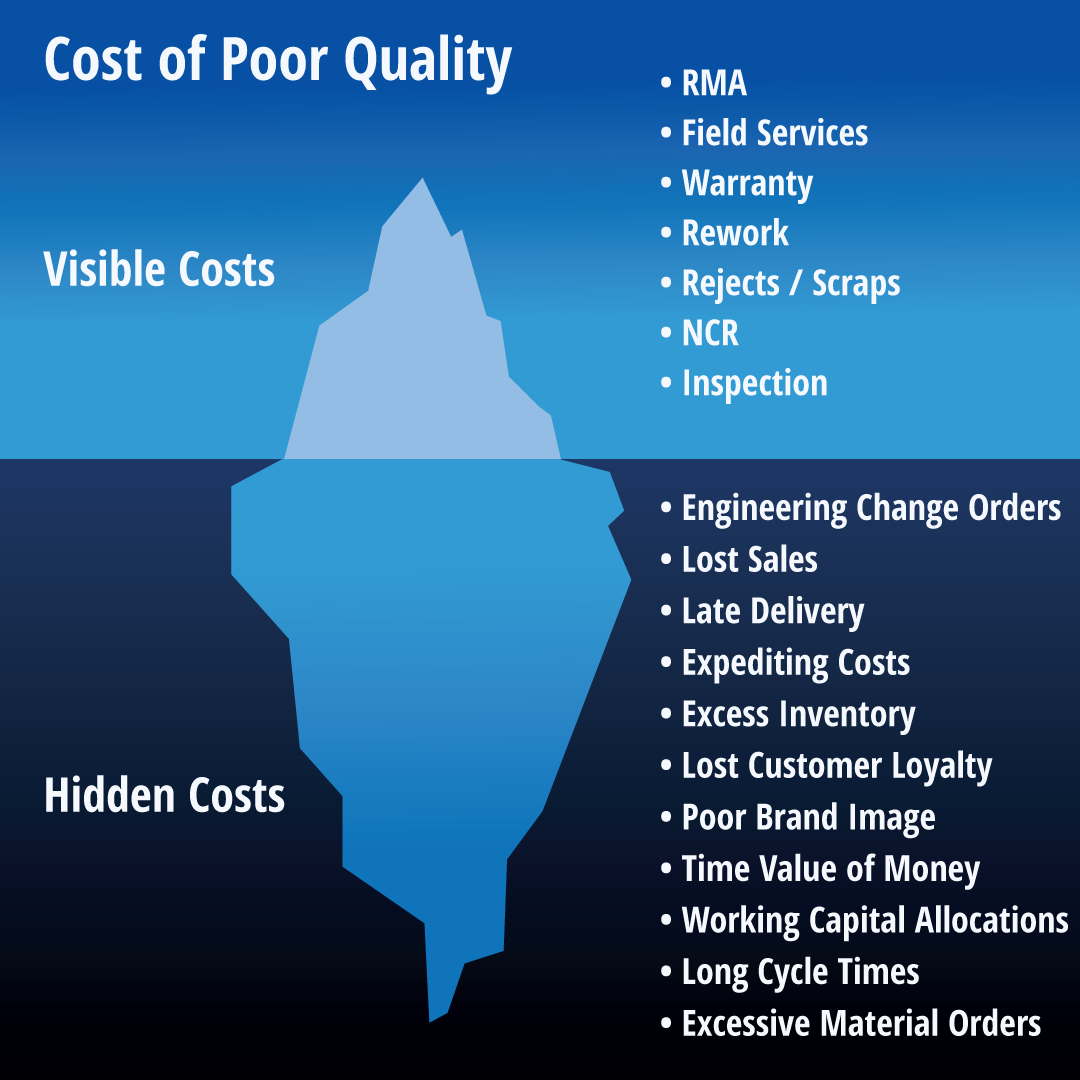

In the fast-paced world of modern manufacturing with expensive materials, many jobs, and very slim margins for errors, maintaining a competitive edge requires more than just skilled management – it demands a seamless integration of key operational elements.

One such integration that stands out in its potential to improve manufacturing quality efficiency is the collaboration between Manufacturing Quality Management Systems (QMS) and Enterprise Resource Planning (ERP) systems.

Operational Silos and Quality Compromises

In many manufacturing organizations, the lack of integration between QMS and ERP systems gives rise to operational silos. This division can lead to critical quality lapses, product “lates,” material waste and reduction of overall productivity. To operate an effective business, data and digital content needs to be accurate, consistent, relevant, accessible, and not duplicated. It needs to be entered seamlessly and not manually entered.

Imagine a scenario where the manufacturing quality data is housed in one system while administrative and operational data resides in another with a human in the middle needing to reconcile the data manually. It is a recipe for miscommunication, data errors, and compliance issues. This disjointed scenario not only jeopardizes product quality, cost, and delivery times, but also places unnecessary burdens on compliance and audit efforts.

The Compromise Cost

The effects of such disjointed systems are far-reaching. Audits become a tedious affair, riddled with inefficiencies and potential errors. The fallout? Hefty fines, tarnished reputation, and an erosion of customer trust. Additionally, the inability to quickly identify and address manufacturing quality issues can result in increased product recalls with subsequent financial setbacks. At a time when the market demands agility, these setbacks are not just inconveniences; they’re potential deal-breakers.

Picture this: a recall due to quality issues that could have been prevented with an integrated Manufacturing QMS and ERP systems. The cost of recalling products, not to mention the damage to brand equity, is a blunt reminder of the price paid for disjointed, non-integrated operational silos.

Unity Through Integration

The remedy to these challenges can be found in the seamless integration of QMS with ERP systems. By fostering collaboration between these two fundamental pillars of business and manufacturing operations, organizations can establish a unified digital thread that diminishes data silos. Quality data then becomes a central part of the entire operational workflow, ensuring that decision-makers have real-time insights into both manufacturing quality and operational metrics.

Let’s think about a scenario where every department, from manufacturing to distribution, is synchronized in real-time, sharing a cohesive data thread. The result? Swift identification and resolution of quality issues streamlined compliance processes, and a proactive approach to risk mitigation. The integration of critical systems doesn’t just bridge the gap – it propels the organization into operational excellence.

Example: Connecting QMS and ERP with HQA Connectors

As we have seen thus far, the integration of ERP and QMS is not just a technological feat; it’s a strategic imperative. The cost of compromise is high, both financially and reputationally. The cost of integration can also be high with the wrong partners. Integrations with custom code or ERP supplied connectors to QMS systems can reach over 6 figures ($100k+) and take months to implement.

Fortunately, using a modern QMS system, like HQA 360, and a modern ERP system with options for open architecture (or APIs) is much easier. For example, creating a new job in HQA 360 software is a swift process, taking only a few minutes. Copying and pasting data from QMS to ERP is relatively common. However, when running hundreds or thousands of jobs each month, that time adds up quickly. As a result, parts are late and working capital goes up.

The HQA ERP Connector removes uncertainties tied to manual job creation. The fear of inadvertently skipping a job, succumbing to typographical errors, or overlooking a critical revision on a new order is now a thing of the past. It seamlessly bridges the gap, performing these intricate tasks automatically between the two systems in the background. The result? More automation, freeing up more time to redirect focus towards tasks of greater significance, and increased productivity!

The Desired Outcome

The painstaking process of data entry is transformed into a real-time automated data sync. No longer is there a need to wrestle with the intricacies of manual input that often is riddled with human errors. Instead, the proven and tested ERP Connector ensures that every job is created accurately, and every piece of information is entered flawlessly.

The manual burden is lifted, allowing quality teams to devote energy to the strategic imperatives that drive businesses forward such as better Reporting and Analytics, and improved utilization of manufacturing machinery.

The HQA ERP Connector is a supported software product, with a lifecycle, enhancements and improvements. It is highly secure and should support compliance needs.

Embrace the power of HQA ERP Connector’s seamless automated integration – where quality and operations converge, and excellence prevails. Break the data silos and improve cost-effectiveness. Elevate your business to a new scalable level. Adopting this software add-on, will positively affect your success.

For more information, visit www.HighQA.com or contact a High QA representative for a no-obligation demo of High QA software, the ultimate manufacturing quality management software.

High QA Software Spotlight Webinar

Streamlining Quality

using HQA 360 and HQA HUB

Thursday, Dec 14, 2023

11:00 am ET

This High QA software spotlight webinar will show you how to easily deal with manufacturing quality processes in your shop and with suppliers. .

From ballooning/bubbling drawings and creating inspection plans, to collecting data and generating FAI/APQP/PPAP submission documents, High QA automates your quality manufacturing processes and brings your suppliers’ manufacturing to your shop floor.

Listen to this spotlight webinar to see how High QA software helps you become more efficient and productive with quality processes both in your shop and across your supply chain.

The High QA Product Spotlight Webinar Series is a series of laser-focused webinars that highlight distinct features of High QA software. These webinars are hosted by High QA professionals.

One Platform. One Database. Infinite Advantages.

Reimagining Manufacturing Quality

As you are probably aware by now, Ford Motor Company released their Customer-Specific Requirements for the IATF 16949 standard in January of 2022. The first question many people have is, “If we have a standard for companies to follow, why are there customer-specific requirements on top of the standard? Doesn’t that negate the need for a standard in the first place?” It’s a very valid point and one that’s under continual scrutiny.

However, instead of focusing on the debate on whether there should or should not be additions to a standard, let’s focus on just what some of those changes are – namely the PFMEA requirements.

As anyone who has been in quality more than 13.2 seconds knows, Microsoft Excel is your friend. It’s literally used in place of documents, links, pictures, calculators, and databases. It’s a complete 1-stop-shop for all things in manufacturing requiring data, forms, and some semblance of interconnectedness between them. However, the one huge black eye it does get, is its lack of interconnectedness between it and other systems (without extensive back-end work).

That brings us to the Ford PFMEA requirements. What is a PFMEA? Briefly, PFMEA stands for Process Failure Mode and Effects Analysis. It is a systematic and proactive approach used in various industries to identify potential failure modes in a process and assess their potential effects. The main purpose of PFMEA is to prevent or mitigate potential problems before they occur, thus improving the overall quality and reliability of the process or product.

The PFMEA process involves a team analyzing each step of a process to identify failure modes – ways in which the process could potentially fail to produce an acceptable part. For each failure mode, the team then assesses its severity (impact on the process), occurrence (likelihood of the failure mode occurring), and detection (likelihood of the failure mode being detected). The outcome of a PFMEA is a prioritized list of potential failure modes, ranked by their Risk Priority Number (RPN), which is calculated by multiplying the severity, occurrence, and detection ratings. This rating allows the team to focus on high-risk areas and develop appropriate actions or controls to prevent the identified potential failures.

From a documentation standpoint, a common practice with a PFMEA is to take the documentation of a part that is similar to the part you are compiling the submission package for and ‘copy and paste’ it over to the new submission package and change the necessary information (failure modes, occurrences, etc.) that are relevant for the new part. This is an inherently error-prone process with items missed or omitted and not entirely reviewed properly or comprehensively. Therefore, when the final PPAP submission package is created, the PFMEA being a vital component of the PPAP, it is rejected, and the supplier has to fix and resubmit.

This is the issue that Ford is correctly trying to prevent.

The new Ford PFMEA standard requires the information associated with the Processes identified on the PFMEA to be generated from a controlled repository of data – ideally, but not specifically, from a database. An Excel-generated PFMEA will not be allowed or approved by FoMoCo.

The High QA PQP module takes this challenge head-on and conforms to the new Ford-specific requirements on top of the IATF 16949 standard by utilizing a database-driven Process Library within the Inspection Manager application. This Process Library contains all necessary “master” information for the Processes at your facility, including Severity, Occurrence, and Detection information and auto-calculated RPN values. This “master” information is used to auto-generate the PFMEA document within High QA.

What does the PFMEA generation process look like? Simply this:

- Balloon the print (High QA automates this too!)

- Identify the characteristics linked to each manufacturing operation

- Link the Process to the Operation (simple pull-down menu)

- Generate the PFMEA

PFMEA Generation will become an automated, consistent, and controlled process that can be done in a few minutes instead of the manual, error-prone Excel method of old.

Contact High QA or visit us at major industry events to find out more about PPAP submission generation using High QA PQP!

For more information, visit www.HighQA.com or contact a High QA representative for a no-obligation demo of High QA software, the ultimate manufacturing quality management software.

Ask the Expert

Thursday, August 10, 2022

11:00 am EDT

Get your answers at our Ask the Expert webinar!

Register for the webinar and join an open Q&A session where your questions drive the webinar. It is the perfect opportunity for you to ask those High QA software questions you have to help you be more productive and efficient.

At High QA, we simplify and automate manufacturing quality.

We are passionate about integrating manufacturing quality processes and streamlining collaboration throughout the supply chain.

Our integrated quality software platform enables manufacturers and customers within their own facility and throughout their supply chain to automate the manufacturing quality process from quoting to delivery that is on-time, on-budget, and on-quality.

As industries progress and advance, so do the standards that govern their operations. One such standard is AS9102. While primarily developed for the aviation, space, and defense industry, this standard is also used in other manufacturing industries where a standardized First Article Inspection (FAI) process is needed.

This standard plays a crucial role in manufacturing and quality with guidelines for planning, manufacturing, and verifying that the processes can produce parts and assemblies that meet the engineering requirements.

In June 2023, the SAE Aerospace Standard (AS) announced an upgrade of the AS9102 standard from Rev. B to Rev. C, bringing about changes that manufacturers must now follow. One of the more important updates is the requirement for more thorough tracking which adds an extra layer of complexity and accountability to the FAI process. This new provision aims to establish complete traceability, ensuring that each product is consistently manufactured at the highest quality.

For some manufacturers, the new requirements introduced in AS9102 Rev. C might appear overwhelming and potentially tedious. The additional required information could demand extra time and resources. However, these measures have been implemented to enhance quality control and traceability, ensuring that every product meets the highest standards of excellence.

What's New in AS9102 Rev. C?

The transition from AS9102 Rev. B to Rev. C has brought about some enhancements that manufacturers need to embrace:

Increased Tracking Requirements

AS9102 Rev. C raises the bar by mandating the tracking of certain items. This level of traceability ensures accountability and transparency throughout the quality process. Manually fulfilling these standards could take a long time and be error-prone, opening the door to expensive mistakes. However, with High QA, tracking and documenting this crucial data becomes a breeze, streamlining your FAI process while effortlessly maintaining compliance.

Improved Documentation

Compliance with AS9102 Rev. C demands comprehensive documentation of the FAI process. With new forms and documentation requirements, manufacturers face the challenge of managing vast amounts of data accurately. High QA, as a robust quality automation platform, simplifies this task by organizing and centralizing all relevant data, allowing your team to generate fully compliant AS9102 Rev. C documents with ease. Say goodbye to the hassle of sifting through paperwork and embrace the efficiency of digital documentation.

Enhanced Alignment with AS9100

AS9102 Rev. C is now more closely aligned with AS9100, the quality management system standard for the aerospace industry. This alignment is designed to facilitate integration and ensure that the FAI process seamlessly complements your broader quality management efforts. High QA not only helps you meet AS9102 Rev. C requirements but also assists in establishing a comprehensive and coordinated quality management system, elevating the overall performance of manufacturing and quality processes.

Form Changes in AS9102 Rev. C

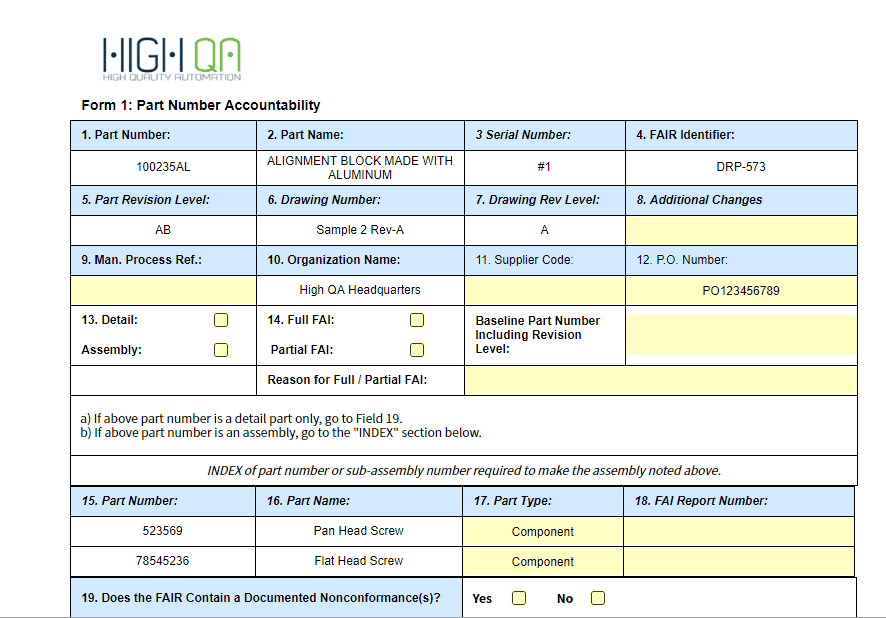

Rather than covering all the standard revisions, let’s look at the changes directly affecting Forms 1, 2, and 3.

For a comprehensive understanding of the changes, you can get a copy of the AS9102 standard through SAE International.

Below is a list of form changes from Revision B and Revision C. The most significant changes between the two versions have been highlighted. Even though some of the changes are minor, it is still important to be aware of them so that you can update FAI processes and train the quality team.

High QA has dynamic fields on many forms. These fields ae usually highlighted with yellow. New data can be entered into the field or existing data can be modified. Some of the forms include an “Add” button to dynamically add more rows for certain fields in boxes. Also, some companies don’t allow for blank fields. High QA includes a parameter, “Fill Empty Field With”, that will input the specified text such as “N/A” into empty fields as applicable.

Form 1

- Field 4 – FAIR Identifier was Field 4 – FAIR Number

- Field 13 – Detail and Assembly was Field 13 – Detail Part and Assembly FAI

- Field 14 – Reason for Full / Partial FAI was Reason for Partial FAI

- Field 17 – Part Type was Field 17 – Part Serial Number

- Field 19 – Does FAIR Contain a Documented Nonconformance(s)? has been added (Sign offs and respective Date fields were renumbered)

- FAI Complete and FAIR Not Complete were removed

- Field 20 – FAIR Verified By was Field 19 – Signature

- Field 22 – FAIR Reviewed/Approved By was Field 21 – Reviewed By

- Field 23 – Date was Field 22 – Date

- Field 24 – Customer Approval and Field 25 – Date are now conditionally required

- Field 26 – Comments was added

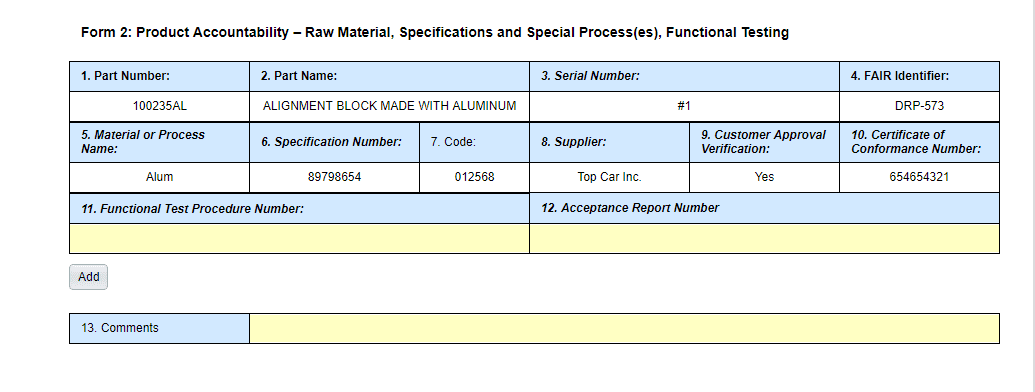

Form 2

- Field 4 – FAIR Identifier was Field 4 – FAIR Number

- Field 14 – Signature and Field 15 – Date have been removed

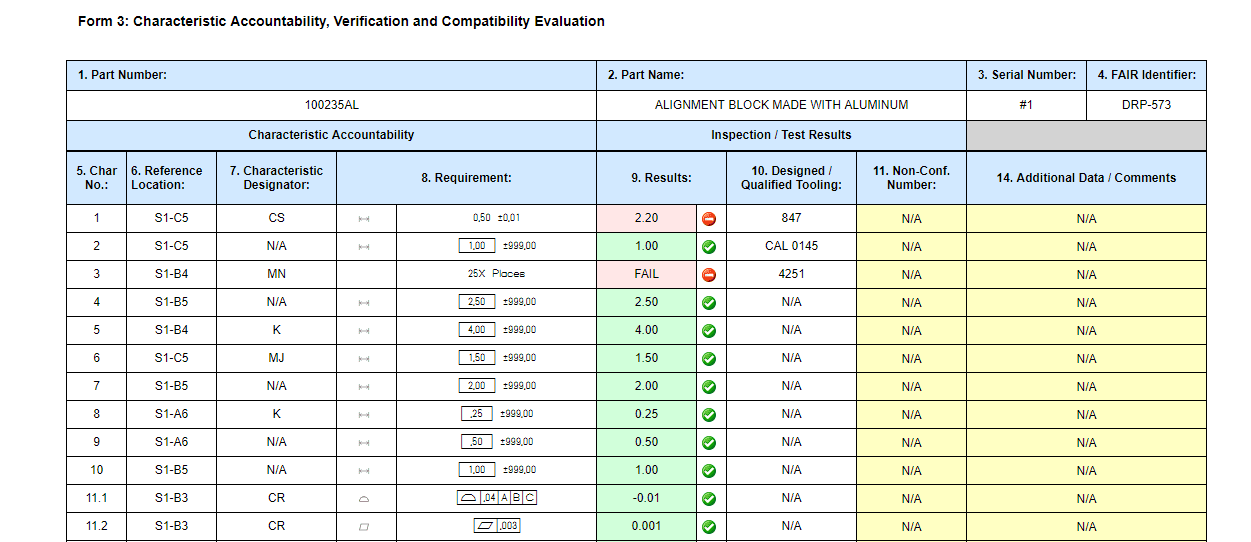

Form 3

- Field 4 – FAIR Identifier was Field 4 – FAIR Number

- Field 12 – Signature and Field 13 – Date have been removed

How High QA Can Help

High QA emerges as the ultimate solution to navigate the complexities of AS9102 Rev. C. This cutting-edge software has been specifically engineered to streamline manufacturing quality automation and optimize the first article inspection process. With High QA, compliance with AS9102 Rev. C is a breeze, offering manufacturers several invaluable advantages.

Comprehensive Data Tracking

High QA makes sure that each measurement is carefully recorded with all the pertinent data. This end-to-end traceability helps develop an accountability culture and is essential to producing an AS9102 Rev. C document that is fully compliant.

Time-Efficient Documentation

High QA automates the data collection and documentation process, significantly reducing the time required for creating comprehensive FAI reports. This not only accelerates the manufacturing quality process but also frees up valuable resources for other critical tasks.

Real-Time Data Insights

High QA enables data-driven decision-making by providing real-time insights into the quality management processes. With the aid of the data analytics and reporting tools that High QA provides, problem areas are pinpointed, and quality processes are streamlined.

Enhanced Productivity

By automating data collection, analysis, and reporting, High QA empowers employees to focus on core quality tasks, leading to improved productivity and overall efficiency within the organization.

Scalability

High QA grows with your needs, making it a future-proof investment. Whether a small business or a large enterprise, High QA adapts to the size and complexity. As a business expands or as industry standards evolve further, High QA is designed to accommodate these changes.

Staying Ahead

In the face of ever-evolving industry standards, staying ahead can be challenging. With AS9102 Rev. C imposing more stringent requirements, companies need tools that make compliance not only achievable but efficient. Embrace the future of manufacturing quality automation with High QA – your reliable partner in achieving AS9102 Rev. C compliance effortlessly.

Investing in High QA has benefits beyond just complying with the updated specifications of AS9102 Rev. C; it also provides cutting-edge technology to keep your company productive, competitive, and dedicated to producing high-quality goods.

Get the tools you need to produce high-quality goods, uphold standards that are industry-leading, and promote success in your company. Embrace the power of High QA now to reach the full potential of your quality process, increase productivity, reduce errors, and meet customer expectations.

Learn more about FAI at /fai/ and request a demo at /schedule-a-demo/

Request a web-meeting demo by requesting a demo now or visiting us at major industry events.

For more information, visit www.HighQA.com or contact a High QA representative for a no-obligation demo of High QA software, the ultimate manufacturing quality management software.

High QA Software Spotlight Webinar

Revision Control

Thursday, July 20, 2023

11:00 am EDT

This High QA software spotlight webinar will show you how to quickly and easily deal with revision control in manufacturing quality processes.

How do you handle print revisions?

Are you still:

- Re-ballooning a print from scratch?

- Re-creating all of your documentation?

- Re-entering all of your data?

Learn how you can quickly and easily manage print revisions in High QA!

With High QA You Can:

- Overlay and easily compare print revisions in just 2 steps

- Easily see changes from one revision to the next

- Adjust, add or remove balloons as needed

- Auto-duplicate your submission documents

- Carry forward existing jobs/samples for ongoing SPC

- Auto-generate new job and samples based on previous revision

Play this recorded spotlight webinar to see how High QA software helps you become more efficient and productive when working with print revisions.

The High QA Product Spotlight Webinar Series is a series of laser-focused webinars that highlight distinct features of High QA software. These 30-minute webinars are hosted by High QA professionals.

One Software. One Solution.

Customer Requirements | Manufacturing Quality | Supply Chain Success

Becoming a More Efficient Shop With the Right Processes and Software

After refining its machining processes for more efficient production, Above All CNC still needed a better way to track its data.

The previous challenge of documenting data manually led not only to Above All implementing ProShop but also to the realization that the shop also needed software to extract inspection data more efficiently for tight-tolerance aerospace parts. For this, they turned to High QA.

High QA is integrated with ProShop, and the two softwares have cut down on inspection planning time, as well as shopfloor inspection time since manual data tracking and documentation are once again eliminated.

”“It saves copious amounts of time,” Rousseau says. “It’s ridiculously helpful. I’m not sure how anyone gets by without it.

With all the complexities that come with generating an aerospace first article inspection, it really holds your hand through the whole process and makes sure it’s done per the standard. It’s just a no-brainer for us.”

Tim Rousseau, Founder and Owner, Above All CNC

Automatically Generate PPAP/APQP Submission Requirements

Meet industry standards and your customer's quality requirements.

See how to efficiently create, manage, support and monitor documentation for industry standards and customer requirements.

Are you a manufacturer in the aerospace, automotive, defense or medical industries trying to keep up with the ever-changing standards? Then don’t miss this webinar where you can learn how to streamline and automatically generate your control plans, PFMEAs, gage R&Rs, SPC control charts, FAIs, PPAPs and other submission requirements.

As a manufacturer, you make parts for many customers. Each customer has their own quality requirements specifying the types of reports they would like to see submitted with each job or order you produce for them.

Keeping track of those requirements can be difficult and time-consuming. Join this webinar to learn how you can automatically generate a complete submission package—with your customers’ specific quality requirements—in less than an hour.

If your company wants to achieve higher profitability and growth, then don’t miss this webinar to see how you can simplify and automate manufacturing quality processes.

Presenter

Tim Hogan

VP of Business Development, High QA